Uses a barcode management system to:

Automatically verify material usage to prevent misuse.

Archive batch information in real time, traceable to raw material sources, usage time, and corresponding production tasks.

Select Language

Select Language

I. Production Capabilities

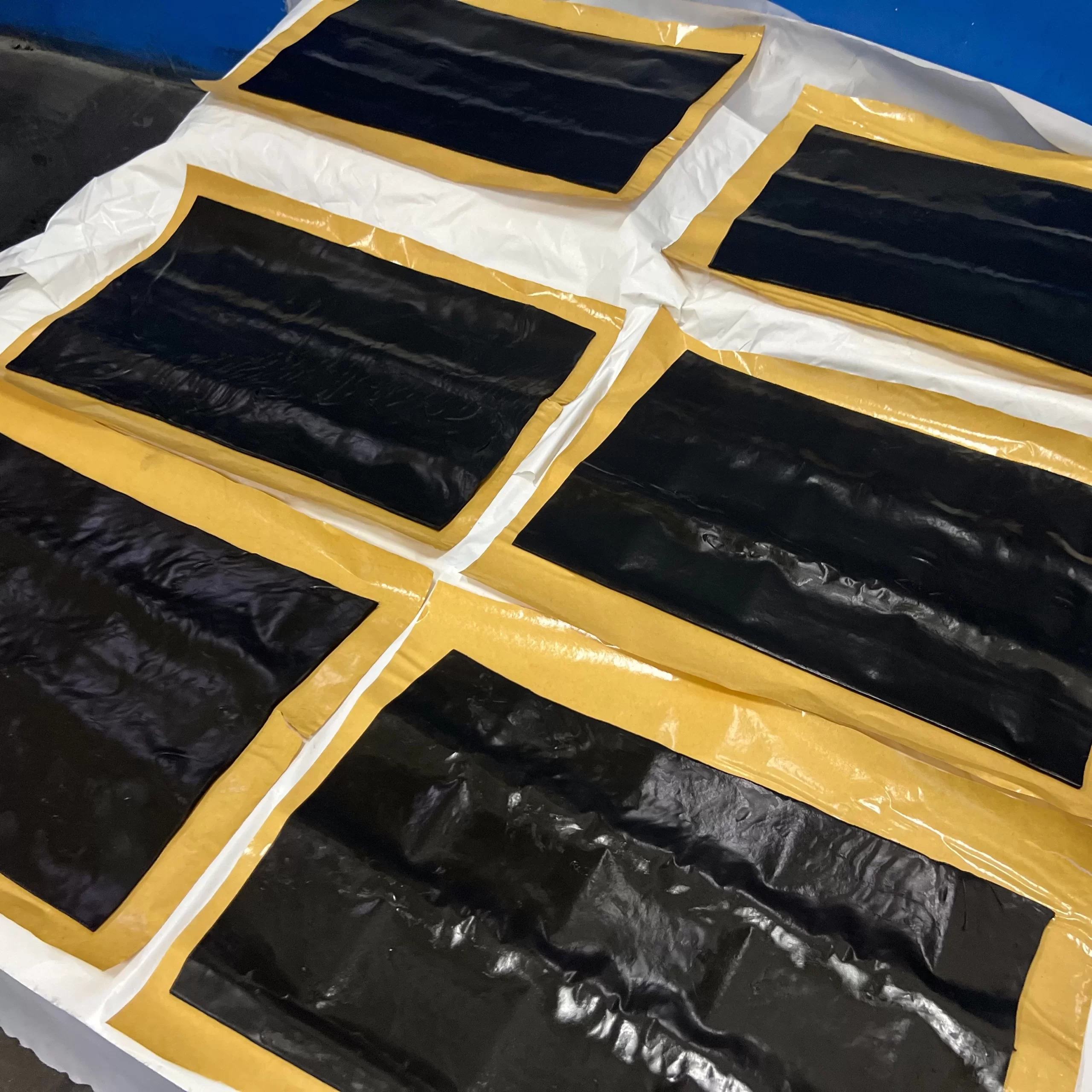

As the technical core and quality origin of the company, the Compound Mixing Workshop specializes in professional mixed rubber production. Equipped with industry-leading production lines and intelligent batching systems, it establishes a production system covering all rubber types:

– 4 fully automated rubber mixing production lines

– 4 preforming equipment units

– Annual production capacity exceeding 10,000 tons

This advanced hardware configuration ensures efficient and stable delivery of multi-category mixed rubber products, meeting customized needs for diverse clients.

II. Core Equipment

(1) Intelligent Batching System

A fully automated material management system enables digital control of production tasks:

Intelligent Batching:Recipe parameters are input into the system, which automatically weighs and proportions materials, eliminating human error.

Dynamic Monitoring:Real-time weight deviation alarms trigger automatically when batching weights exceed set thresholds, ensuring all materials pass standard verification before proceeding to the next process.

Process Traceability:Full-process digital records enable precise correlation between recipes and materials.

(1) Preforming Processing Equipment

Composition: 2 cold-feed precision extruders + 2 hot-feed preforming machines

Technical Breakthrough: Replaces traditional manual cutting and weighing.

Performance Advantages:

Weight tolerance controlled within ±0.2g

Vulcanization production efficiency increased by 40%

Rubber material utilization improved by 10%

III. Quality Control System

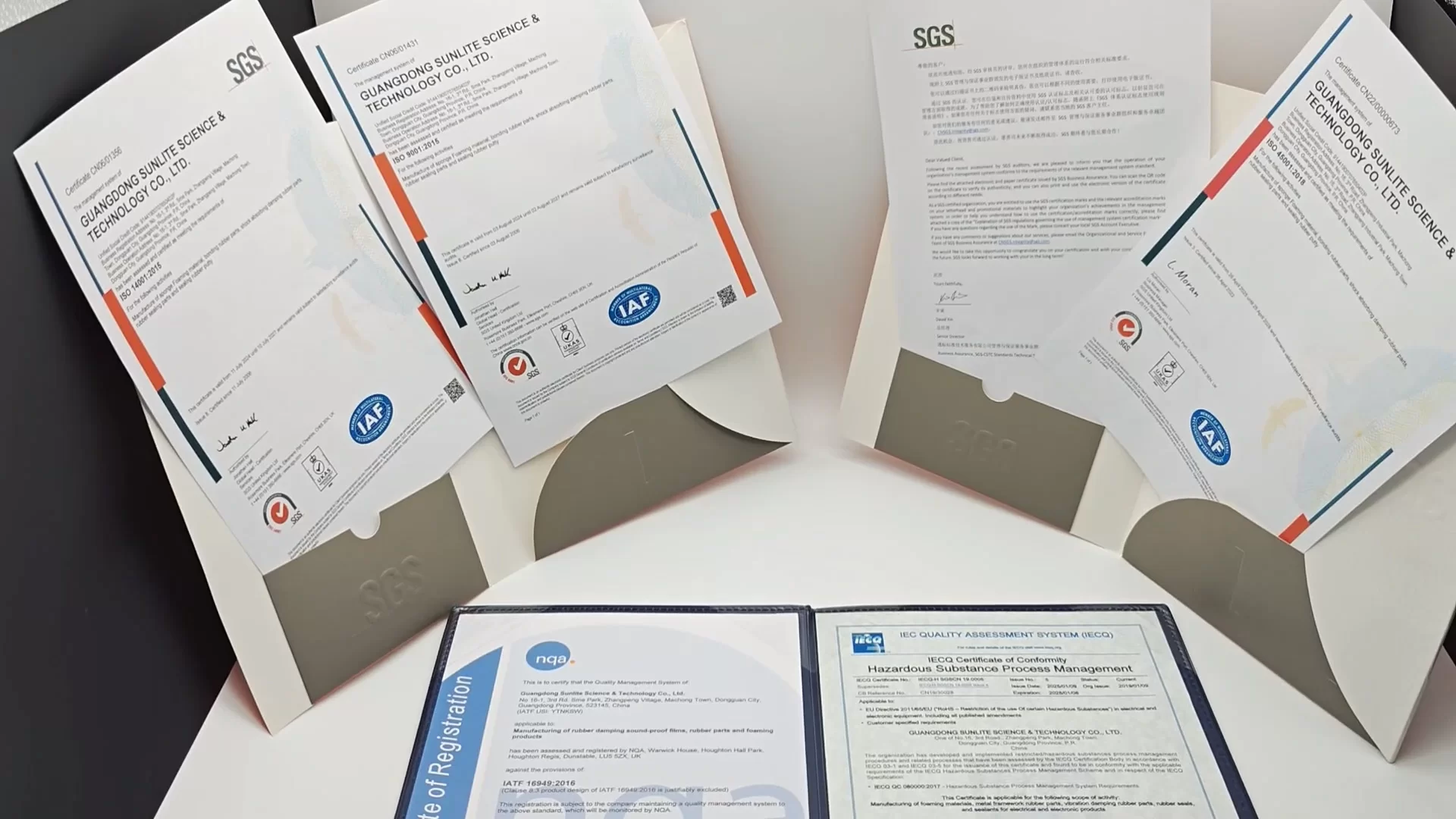

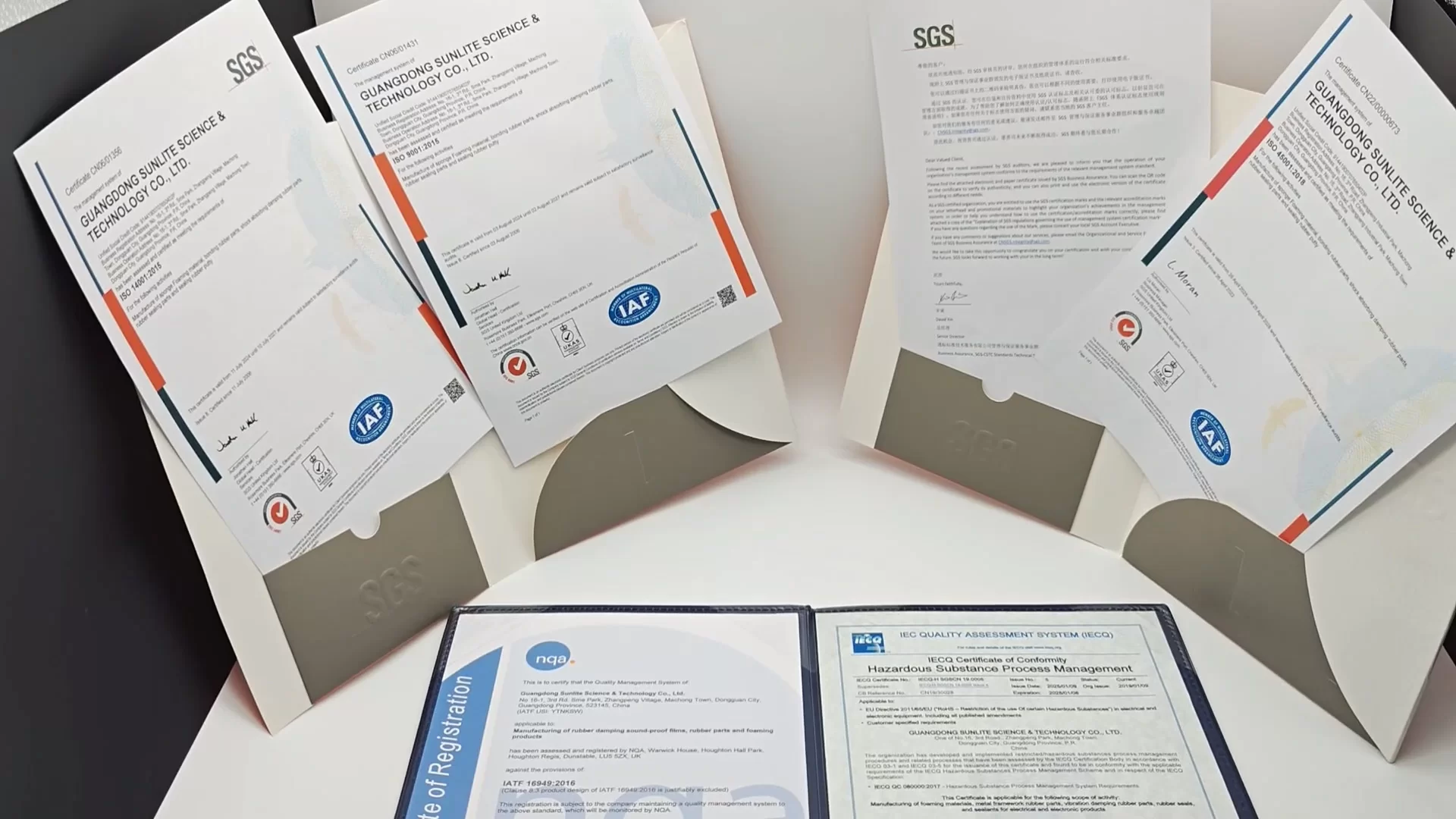

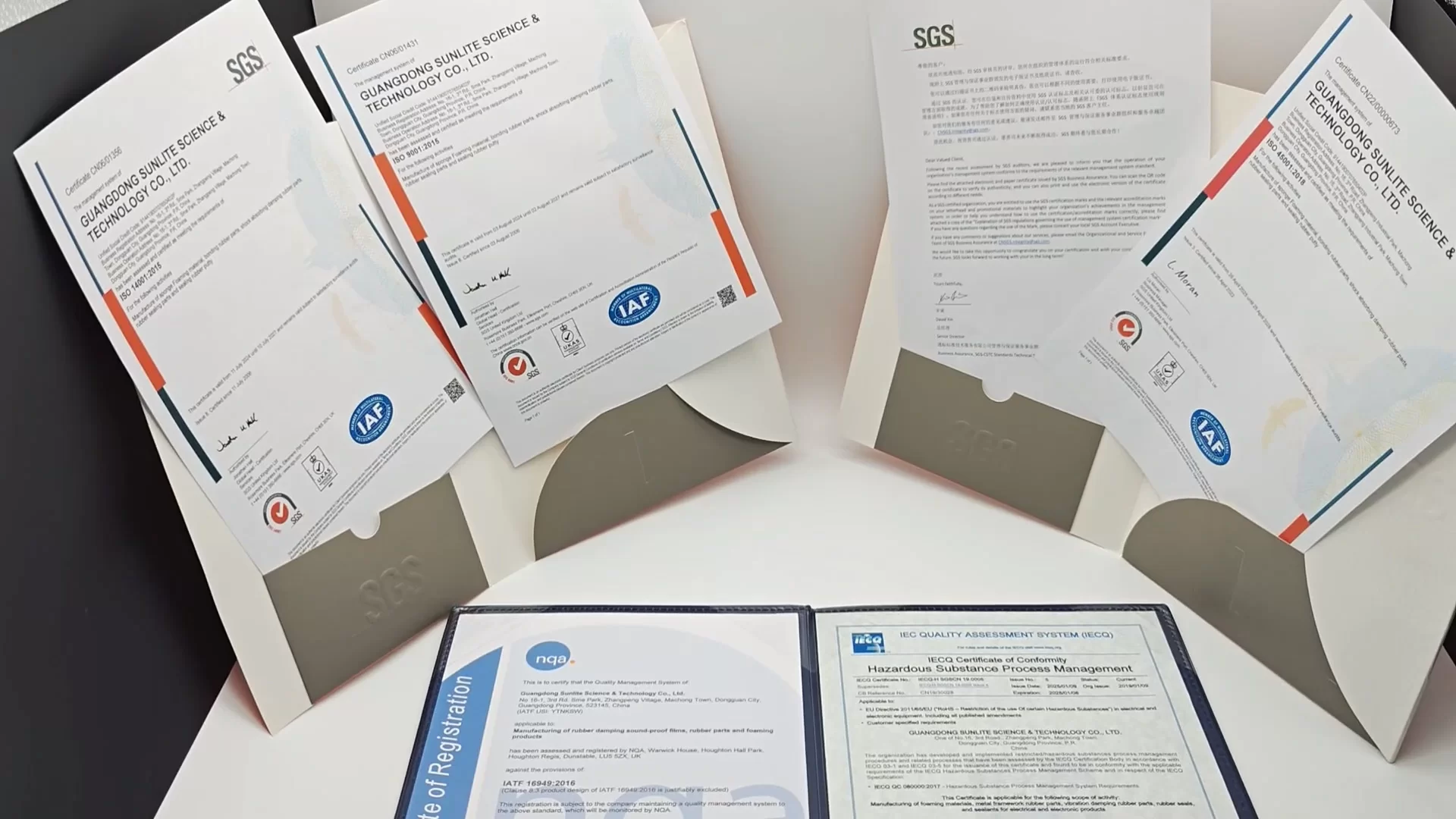

Management System Certifications

A full-process quality control framework built through international authoritative certifications

ISO 9001 Quality Management System

ISO 45001 Occupational Health and Safety Management System

ISO 14001 Environmental Management System

IATF 16949 Automotive Quality Management System

Process Control Equipment

Metal Foreign Object Detection: Online metal detectors monitor in real time, automatically alarming and removing metal impurities.

Multi-Stage Filtration System: Uses 80-mesh, 100-mesh, and 120-mesh filters for graded filtration based on rubber type, ensuring no impurity residue.

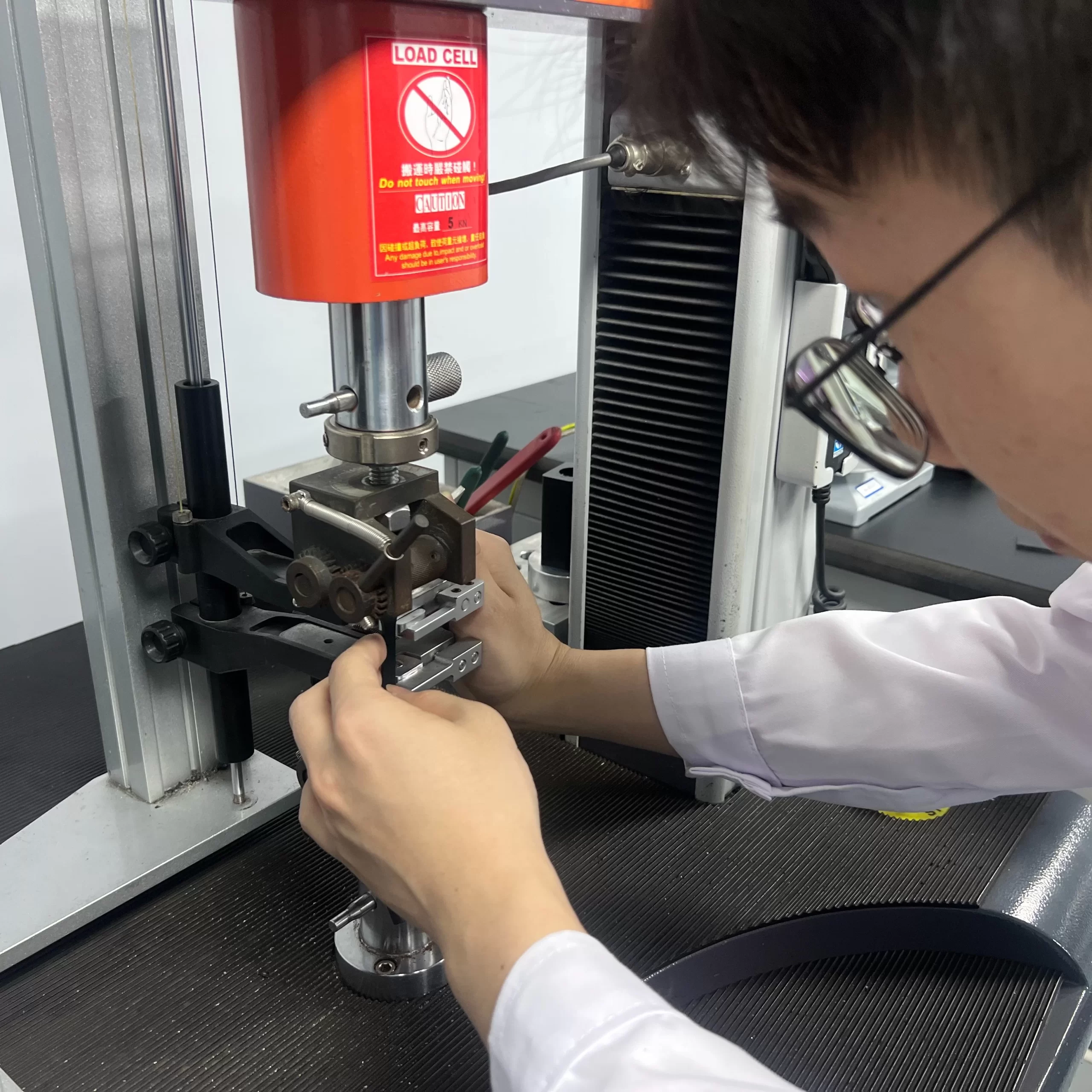

Laboratory Testing Capabilities

Equipped with a CNAS national-level laboratory

Test items include:Vulcanization characteristics (rheological testing)

Mooney viscosity

Physical and mechanical properties

Full-batch type testing is implemented to ensure each batch meets technical specifications.

IV. Full-Process Traceability System

1. Raw Material Traceability

Uses a barcode management system to:

Automatically verify material usage to prevent misuse.

Archive batch information in real time, traceable to raw material sources, usage time, and corresponding production tasks.

2.Production Process Traceability

Production tasks are issued fully digitally, with the system automatically recording:

Production time and equipment information

Batching details and process parameters

Batch output and process control data

3.Quality Inspection Traceability

Electronic management of inspection records

Sample retention specifications:

Marked with unique product codes

Recorded production and inspection dates

Complete quality archives established for full lifecycle traceability

Through the triple guarantees of equipment intelligence, systematic management, and digital traceability, the Compound Mixing Workshop maintains industry-leading process control capabilities, delivering high-quality, reliable mixed rubber products and services to clients.