As new energy vehicles and intelligent cockpit technologies evolve rapidly, ride comfort has become a key battleground for automakers seeking differentiation. Addressing the environmental drawbacks and performance limitations of traditional asphalt-based damping sheets, a new generation of polymer composite damping materials is reshaping automotive NVH (Noise, Vibration, and Harshness) control standards through molecular-level innovation.

Technological Breakthrough: A New Paradigm of Energy Conversion

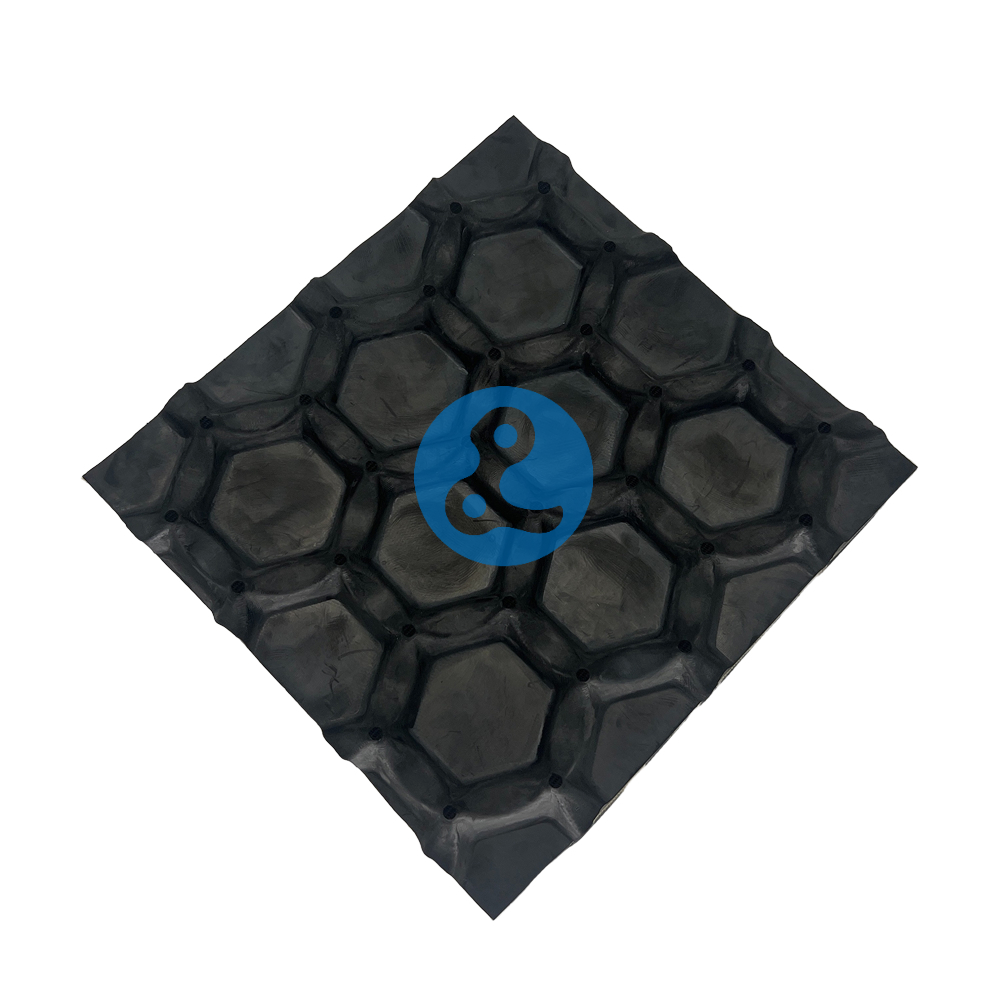

The material adopts a gradient cross-linked polymer network structure. When vibration energy is introduced, controllable internal friction occurs between molecular chains:

① Low-frequency vibrations (20–200 Hz) are dissipated through chain segment orientation;

② Mid-to-high frequency vibrations (200–2000 Hz) are absorbed via friction in micro-phase separated structures.

This dual “damping-energy absorption” mechanism allows the material to maintain over 90% vibration reduction efficiency in extreme environments ranging from -40°C to 120°C—over 50% improvement compared to traditional materials.

Performance Leap: A Four-Dimensional Upgrade

Full-Frequency Coverage: Precisely targets multiple disturbance bands, including engine idling (80 Hz) and high-speed tire noise (1000 Hz).

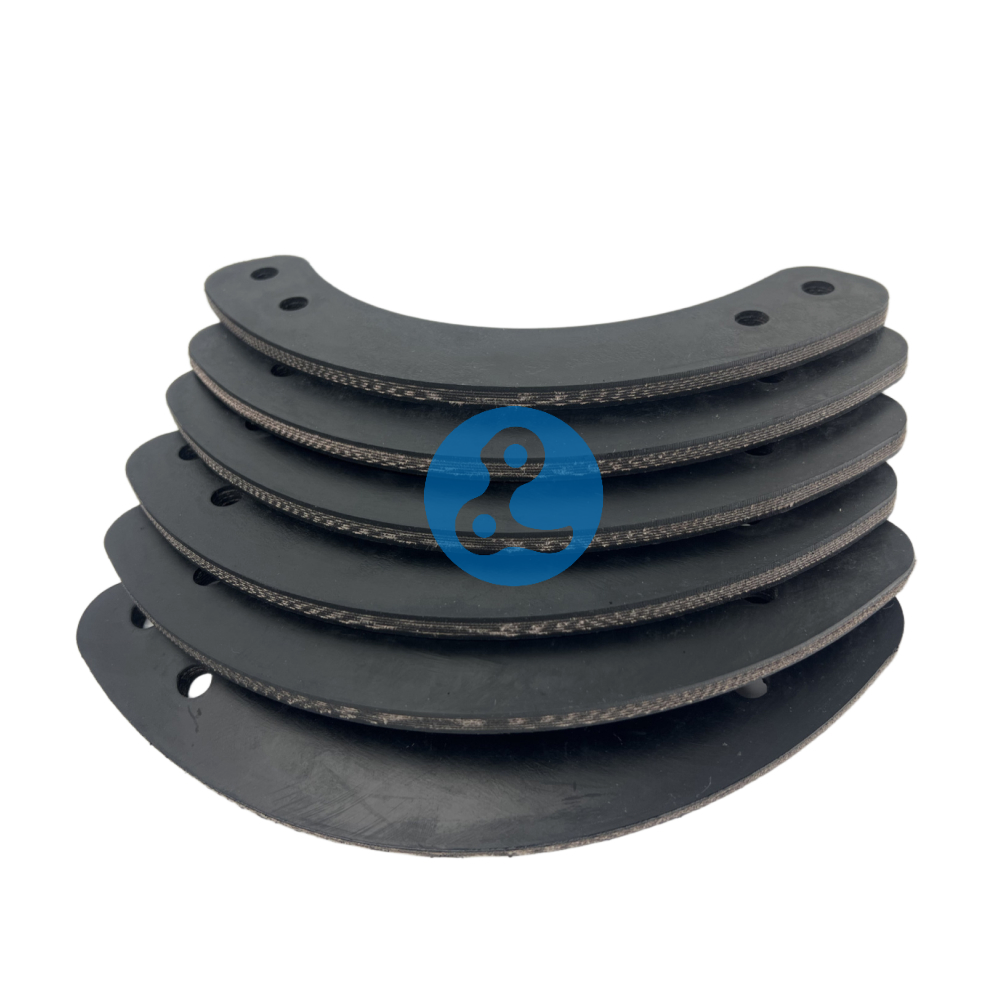

Lightweight Revolution: Density reduced to 0.8 g/cm³—50% lighter than traditional materials—boosting EV range by 8–12 km.

New Environmental Standards: Utilizes bio-based plasticizers and halogen-free flame retardants, meeting 28 international certifications such as REACH and ELV.

Smart Adaptation: Material stiffness changes less than 5% with temperature variation, making it ideal for integration with advanced structures like carbon fiber car bodies.

Proven Value: Quantified User Experience Enhancement

Test data from a German luxury SUV show:

① Idling noise reduced to 38 dB(A), 2.3 dB lower than competing products;

② Wind noise controlled under 65 dB(A) at 200 km/h;

③ Vertical acceleration over speed bumps reduced by 40%, enhancing seat support by 30%.

Even more notable, the material boosts mid-frequency audio clarity by 25%, unlocking greater potential for in-car entertainment systems.

As materials genomics continues to evolve, next-generation damping materials are moving toward self-healing and programmability. This shift from passive absorption to active regulation may redefine the boundaries of in-cabin quietness, creating a “library-grade” mobile acoustic experience for users.

Select Language

Select Language