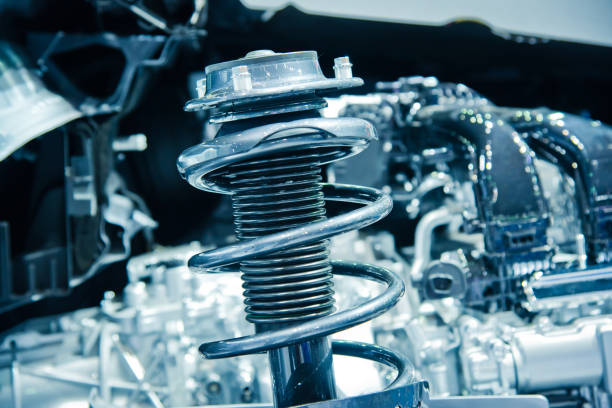

In high-frequency impact tools such as electric nail guns, rubber damping blocks serve as key vibration-reducing components. Their performance directly affects equipment lifespan and operator safety. Traditional rubber materials often suffer from poor impact resistance, leading to premature equipment failure or hand injuries for users.

I. Technical Background & Core Value

In high-frequency impact tools such as electric nail guns, rubber damping blocks serve as key vibration-reducing components. Their performance directly affects equipment lifespan and operator safety. Traditional rubber materials often suffer from poor impact resistance, leading to premature equipment failure or hand injuries for users.

Xinli Technology has developed a high-impact elastomeric material using advanced molecular engineering and process innovation, increasing impact energy absorption to more than three times that of conventional rubber (15–50J). This represents a revolutionary solution for the power tools industry.

II. Three Core Technological Breakthroughs

|

Technical Dimension |

Key Innovation |

Technical Advantages |

|

Molecular Design |

Polymer matrix with low glass transition temperature (-40°C) + 3D crosslinked network structure |

Elongation at break exceeds 500%; maintains high elasticity even in low temperatures; adapts to extreme working conditions. |

|

Composite Reinforcement |

Nano-reinforced additives + strong intermolecular interactions |

Withstands over 200,000 impact cycles without damage; significantly improves material durability. |

|

Process Control |

Precise vulcanization temperature (150±5°C) + multilayer compression molding |

Balanced hardness (50–90 Shore A) and tear strength (>100N/mm); ensures both flexibility and strength. |

III. Performance Under Extreme Conditions

Operating Temperature: -40°C to 175°C

Impact Energy Range: 15J to 50J

Impact Resistance Cycles: Up to 300,000 times

Vibration Damping Rate: Reduces rebound vibration by over 70%

Application Scenarios:

Construction: Ensures stability of high-frequency tools in high-altitude operations

Automotive Manufacturing: Precise vibration control on welding and assembly lines

Industrial Maintenance: Equipment protection in extreme temperature environments

IV. Industry Impact & Market Outlook

Breakthrough in Technical Barriers: Overcomes the performance limitations of traditional rubber through nano-reinforcement and molecular chain design.

Enhanced Cost Efficiency: Extends tool lifespan by 3–5 times, significantly reducing maintenance costs for enterprises.

Improved User Experience: 70% reduction in vibration greatly minimizes operator fatigue, aligning with ergonomic design trends.

V. Technical Expansion & Future Outlook

Xinli Technology’s high-impact material technology can be expanded to the following sectors:

Aerospace: Precision damping systems for sensitive instruments

New Energy Vehicles: Impact protection for battery packs

Smart Equipment: Shock-absorbing joints in robotics

For detailed technical specifications or customized solutions, please contact

Xinli Technology Co., Ltd.

Consultation: +86-13825745676

Select Language

Select Language